HIGH STANDARD VALVES FOR NON-STANDARD CONDITIONS

HIGH STANDARD VALVES FOR NON-STANDARD CONDITIONS

Zwick is a leading manufacturer of metal‐seated triple offset butterfly valves known as series TRICON,

the check valves, called TRI‐CHECK and the TRI‐BLOCK series, Zwick’s Double Block and Bleed Design.

40 years experience in design and production of valves guarantee high standard products. ZWICK valves are produced state‐of‐the‐art. The triple offset butterfly valves are specially designed for critical services where they are used as shut off and control valves. The in‐house design enables offering customized solutions for individual applications like the global Industries of Oil and Gas, Chemical, Petrochemical, Energy, Offshore and Steel.

Downloads: ZWICK_Technical_Brochure_06_2014 ZWICK_Company_Brochure_engl_11_2012

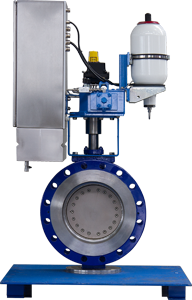

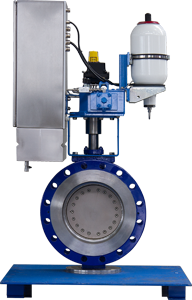

TRI‐CON

TRI‐CON valves incorporate a unique third offset design with a true cone‐in‐cone seating and a reliable zero‐leakage performance and allow bi‐directional tightness.

The number of unique technical attributes of the product, as the cone‐in‐cone seating design with the multiple laminations and the metal seat makes the series TRI‐CON to an allrounder for many different industrial applications. Zwick valves are used for industrial and exhaust gases, liquids, hot water or steam at lowest as well at high temperature zones up to 815°C.

The Zwick self‐centering disc design that is keyed to the shaft

accommodates differential thermal expansions of the disc and the shaft. The triple offset geometry assures frictionless running without radial loading of the seal ring and break‐away torque. The TRI‐CON series reaches a superior unrivaled life time cycle. For critical services a patented sealed bearing solution is offered to prevent fouling of the bearing associated with line media. Zwick’s zero‐leakage bearing design assures that no line media will migrate into

bearings cavity.

http://zwick-gmbh.de/en/tri-con/ |

|

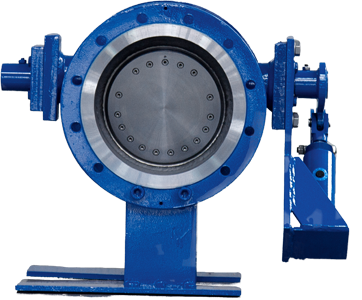

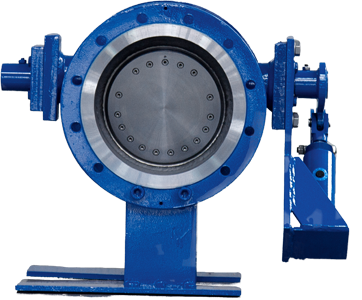

TRI‐CHECK

The check valve TRI‐CHECK combines all the benefits of the Series TRI‐CON in a non‐return valve. Triple‐offset design with a wide

seat angle and a true cone in cone, no rubbing while moving and absolute zero leakage performance. The TRI‐CHECK is equipped

with a hydraulic damper and a counter weight. The damper can be adjusted to the actual installation conditions in which the valve

will be used.

The damping system not only reduces the risk of pressure surges due to waterhammer because of its closing characteristic, it also prevents the disc to slam in the seat. Instead the

disc closes in a smooth movement which can be adjusted, so that the valve closes slowly in the last degrees of movement to protect the sealing parts. The Check Valve Series TRI‐CHECK has proved to be the ideal non‐return valve for single or multiple pump protection application for the last two decades. Another benefit of the valve is the variety of features.

Beside the nonreturn function the valve can be used as a combined check and isolating valve or as a check valve with power assisted closing and opening.

The Series TRI‐CHECK uses a seat design in which the seat is not parallel to the flange facing in the body. Instead there is a certain angle between centerline and seat in the body as can be seen in the left drawing. As a consequence the general free area will be increased, so that the fluidic resistance of the valve will be decreased. Another advantage is that the valve

travel will be reduced, so that the valve reaches its ideal position in the flow much faster.

Zwick also uses the latest EFD Simulation technology to optimize the design of the series TRICHECK and to achieve the best possible hydrodynamical characteristics.

http://zwick-gmbh.de/en/tri-check/ |

|

TRI‐BLOCK

The Double Block and Bleed design features every technical advantage which the series TRICON has plus there is a true double block and bleed feature which

delivers zero leakage. By using this design, the former two valve system with a spool piece becomes obsolete. This fact is not only

important for installation since you have to install only one valve body in the pipeline, but also only one actuator or gearbox is

required With Zwick’s unique design of the linkage between the two shafts, the user is able to actuate both shafts with only one actuator

and reach zero leakage with the two available sealing surfaces.

The design of the linkage forgives any dimensional changes due to thermal differences in the valve. The redundant zero leakage

performance of this valve is the ideal valve solutions for several critical processes where absolute zero leakage and pipe inspection via the bleed port are required. Applications like

multi‐product manifolds, meter stations, tank storage isolation or hydrant isolation are very sensitive to leakage and the Double Block and Bleed design would be an ideal fit.

http://zwick-gmbh.de/en/tri-block/ |

|

TRI‐SHARK

TRI‐SHARK control valves provide all the latest in control valve innovation, technology and valve acoustics. Our control valves are

created that exhibit significant improvements in performance, simplicity, and economy. TRI‐SHARK control valves have excellent throttling characteristics and provide aerodynamic noise attenuation, and liquid cavitation reductions. They are suitable for a wide range of services from cryogenic temperatures, up to 850°F, including liquids,

gases and steam.

As the butterfly vane turns within the Throttling Trim Cartridge, the flow is first controlled via the characterized clearance between the disc edge and the solid, tapered portion of the Cartridge; then through the multiple, optimized slots; and finally, through the additional open area of the valve.

http://zwick-gmbh.de/en/tri-shark/ |

|

HIGH STANDARD VALVES FOR NON-STANDARD CONDITIONS

HIGH STANDARD VALVES FOR NON-STANDARD CONDITIONS